Electric Vehicle Design

Electric vehicle design focuses on creating efficient, eco-friendly transportation solutions by integrating advanced technologies and sustainable materials. Key elements include optimizing aerodynamics to reduce drag, minimizing weight through lightweight materials like aluminum and carbon fiber, and maximizing interior space for passengers and batteries.

The design process also emphasizes sleek, futuristic aesthetics while ensuring safety and comfort. Additionally, engineers work to enhance the vehicle’s electric drivetrain, incorporating regenerative braking systems and high-performance motors. Attention to user-friendly interfaces, seamless connectivity, and modern infotainment systems also play a crucial role in enhancing the driving experience in electric vehicles.

Table of Contents

Electric Vehicle Design: A Comprehensive Overview

The rise of electric vehicles (EVs) represents a transformative shift in automotive technology, design, and consumer behavior. As global concerns about climate change and air pollution grow, EVs offer a sustainable alternative to traditional internal combustion engine (ICE) vehicles. However, designing an electric vehicle involves much more than simply replacing a gasoline engine with an electric motor. It requires a comprehensive understanding of aerodynamics, battery technology, software integration, safety considerations, and user experience. This blog post will dive deep into the complexities of EV design, covering the main aspects that make electric vehicles unique and innovative.

Introduction to Electric Vehicle Design

Electric vehicles are reshaping the future of transportation, emphasizing efficiency, sustainability, and advanced technology. The fundamental design principles of EVs differ significantly from conventional vehicles, requiring innovative approaches to powertrain architecture, battery management, and vehicle aesthetics.

Electric vehicle design focuses on four main pillars:

- Efficiency: Maximizing the range and minimizing energy consumption.

- Sustainability: Using eco-friendly materials and processes.

- User Experience: Enhancing driving experience with seamless technology integration.

- Safety: Protecting occupants and pedestrians through advanced safety features.

Powertrain Design and Architecture

The powertrain is the heart of any vehicle, and for EVs, it includes the electric motor, power electronics, transmission (if present), and the energy source – the battery. Unlike traditional vehicles, EVs often have fewer moving parts, leading to higher efficiency and reduced maintenance requirements.

- Electric Motor Types: The choice of motor impacts the performance, efficiency, and cost of the EV. Common motor types include:

- Induction Motors: Known for their robustness and low cost, induction motors are widely used, notably in early Tesla models.

- Permanent Magnet Synchronous Motors (PMSM): These motors offer high efficiency and power density, making them popular in modern EVs.

- Switched Reluctance Motors: These are less common but are gaining attention due to their simplicity and high reliability.

- Battery Management Systems (BMS): The BMS is a crucial component that monitors the battery’s health, state of charge, and temperature. It ensures that the battery operates within safe parameters, maximizing its lifespan and performance.

- Thermal Management: Maintaining optimal temperatures for the battery, motor, and power electronics is vital. Effective thermal management prevents overheating, enhances efficiency, and ensures safety.

- Regenerative Braking: This system captures kinetic energy during braking and converts it back into electrical energy to recharge the battery, enhancing the overall efficiency of the EV.

Battery Technology and Challenges

The battery is the most critical and expensive component of an EV, often accounting for 30-50% of the vehicle’s total cost. Its design directly impacts the range, charging time, safety, and overall performance of the EV.

- Types of Batteries:

- Lithium-Ion Batteries: Currently the most popular choice due to their high energy density, long cycle life, and relatively low self-discharge rates.

- Solid-State Batteries: A promising next-generation technology that offers higher energy density, faster charging times, and improved safety by eliminating liquid electrolytes.

- Lithium Iron Phosphate (LFP) Batteries: These are safer and have a longer cycle life but offer lower energy density compared to lithium-ion.

- Battery Pack Design: The layout and packaging of the battery cells within the vehicle significantly affect weight distribution, space utilization, and safety. Design considerations include:

- Modular Design: Allows for easier maintenance and the potential for battery swapping.

- Integration with the Chassis: Some designs integrate the battery pack directly into the vehicle’s structure, improving rigidity and safety.

- Charging Systems:

- AC Charging: Typically slower, used for home charging solutions.

- DC Fast Charging: Provides rapid charging, crucial for long-distance travel.

- Wireless Charging: An emerging technology that offers convenience by allowing charging without physical connectors.

- Safety Measures: Batteries are susceptible to thermal runaway, a dangerous condition where the battery heats uncontrollably. Safety measures include fire-resistant materials, robust cooling systems, and fail-safe shutdown mechanisms.

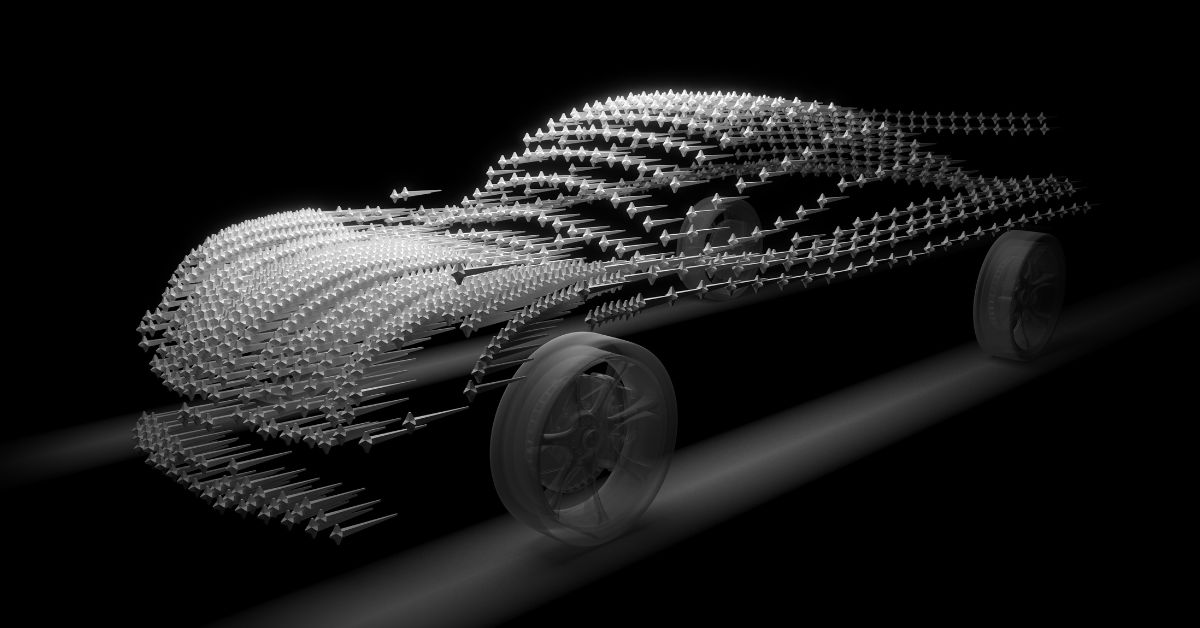

Aerodynamics and Lightweight Materials

Aerodynamics plays a crucial role in EV design, directly influencing the vehicle’s efficiency and range. The lower drag coefficients of EVs help reduce the energy needed to overcome air resistance, making the vehicle more efficient at high speeds.

- Sleek Designs: EVs often feature smoother, more streamlined shapes with minimal front grilles, reducing drag. Concepts like flush door handles and underbody covers further improve aerodynamics.

- Active Aerodynamics: Some EVs utilize active aerodynamic elements, such as adaptive spoilers and grille shutters, which adjust based on speed and driving conditions to optimize airflow.

- Lightweight Materials:

- Aluminum and Magnesium Alloys: Used extensively in the body and chassis to reduce weight without compromising strength.

- Carbon Fiber: Offers significant weight savings but is costly, thus often reserved for high-performance models.

- High-Strength Steel: Balances cost, weight, and structural integrity, commonly used in crash structures.

Interior Design and User Experience

The absence of a bulky engine and transmission allows for more flexibility in the interior layout of an EV. Designers can reimagine space utilization, enhancing comfort and functionality.

- Spacious Interiors: EVs often have flat floors, allowing for more legroom and innovative seating arrangements. Some models even feature lounge-like interiors with swiveling seats.

- Infotainment and Connectivity: Modern EVs are equipped with advanced infotainment systems, integrating touchscreens, voice control, and over-the-air (OTA) updates that keep the software current.

- Minimalist Design: Many EVs, like Tesla’s Model 3, adopt a minimalist approach with fewer physical buttons and a focus on digital interfaces, enhancing the futuristic feel of the vehicle.

- Sustainable Materials: Automakers are increasingly using recycled or renewable materials for upholstery, trim, and other interior components, aligning with the eco-friendly ethos of EVs.

Safety Innovations in EV Design

Safety is paramount in EV design, especially with the high voltages and large battery packs involved. Modern EVs incorporate a variety of safety features that protect both occupants and the vehicle’s electrical systems.

- Battery Safety: Ensuring the battery is secure in a crash is critical. Battery packs are often encased in rigid structures with crumple zones designed to absorb impact energy.

- Crash Testing and Structural Integrity: EVs typically have lower centers of gravity due to the heavy battery pack, which can improve handling and reduce rollover risk. However, the structural design must account for unique weight distributions.

- Advanced Driver Assistance Systems (ADAS): Many EVs come equipped with ADAS features like adaptive cruise control, lane-keeping assist, and autonomous emergency braking, enhancing overall safety.

- Pedestrian Safety: Because EVs are quieter, there is a risk that pedestrians may not hear them approaching. Regulations often require EVs to emit artificial sounds at low speeds to alert pedestrians.

Software and Smart Systems

Software plays a crucial role in the operation and user experience of an EV. From power management to autonomous driving features, software integration is essential for modern EVs.

- Vehicle Control Systems: Advanced software manages everything from power distribution between the motor and battery to regenerative braking and energy recovery systems.

- Autonomous Driving: EVs are often seen as the ideal platform for autonomous technology due to their drive-by-wire systems, which can be easily integrated with AI-based control algorithms.

- Over-the-Air Updates: OTA updates allow automakers to improve vehicle performance, fix bugs, and add new features without requiring a visit to the dealership. This ability to continuously update software keeps the vehicle fresh and responsive to new technological advancements.

- Smart Charging Management: Intelligent charging systems can optimize when and how an EV charges, considering factors like electricity costs, grid demand, and battery health.

Design Challenges and Future Trends

Designing electric vehicles is not without its challenges. The rapid pace of technological change, evolving consumer expectations, and regulatory pressures all influence how EVs are designed.

- Range Anxiety and Charging Infrastructure: Despite improvements in battery technology, range anxiety remains a significant barrier for consumers. Expanding charging infrastructure and reducing charging times are critical areas of focus.

- Cost Reduction: Batteries remain the most expensive component of an EV. Research into alternative materials, improved manufacturing techniques, and economies of scale are crucial for making EVs more affordable.

- Sustainability in Manufacturing: The environmental impact of battery production, including mining and disposal, poses challenges. Efforts are underway to develop more sustainable manufacturing processes and recycling methods.

- Vehicle-to-Grid (V2G) Integration: Future EVs may not just consume energy but also provide it back to the grid during peak demand times, enhancing energy resilience and supporting renewable energy sources.

- Customization and Personalization: The digital nature of EVs allows for greater personalization options, from performance tuning to customizable digital dashboards. This trend is expected to grow, offering unique user experiences tailored to individual preferences.

FAQs About Electric Vehicle Design

Q1. What are the key components of electric vehicle design?

EVs consist of key components like the electric motor, battery, inverter, battery management system, and onboard charging system.

Q2. How does the design of an EV differ from a conventional car?

EVs lack a traditional internal combustion engine and drivetrain, relying on electric motors and batteries, leading to different layouts and space-saving designs.

Q3. What types of electric motors are used in EV design?

EVs commonly use three types of motors: DC brushed, DC brushless, and AC induction motors, with AC induction motors being the most popular.

Q4. What is the role of aerodynamics in electric vehicle design?

Aerodynamic efficiency is critical in EV design to reduce drag and improve energy efficiency, increasing the vehicle’s range.

Q5. How does battery placement affect EV design?

Batteries are usually placed in the underbody to lower the center of gravity, improve stability, and free up space inside the vehicle.

Q6. How do cooling systems impact electric vehicle design?

Effective thermal management is essential to prevent overheating of the battery and electric motor, ensuring optimal performance and longevity.

Q7. What materials are used to reduce the weight of electric vehicles?

Lightweight materials like aluminum, carbon fiber, and advanced composites are used to reduce weight and improve energy efficiency.

Q8. How do designers optimize EV range?

EV range is optimized through lightweight construction, improved aerodynamics, efficient powertrain systems, and regenerative braking systems.

Q9. What are the safety considerations in electric vehicle design?

EVs are designed with reinforced battery casings, advanced cooling systems, and electrical insulation to mitigate fire risks and ensure occupant safety.

Q10. How does regenerative braking influence EV design?

Regenerative braking systems are integrated into EVs to recover energy during deceleration, extending the vehicle’s range and improving efficiency.

Q11. What design challenges are faced when integrating fast-charging capabilities?

Designing for fast charging involves optimizing the battery’s thermal management and electrical system to handle high power loads without degrading performance.

Q12. What role does software play in EV design?

Software controls critical functions like battery management, energy efficiency, regenerative braking, and motor performance, making it a vital aspect of EV design.

Q13. How do electric vehicle designs cater to different driving environments?

EV designs are adapted with all-wheel drive systems, torque vectoring, and specific battery configurations to perform well in urban, off-road, and long-distance driving conditions.

Q14. How is noise reduction addressed in electric vehicle design?

EVs are inherently quieter, but noise reduction techniques focus on minimizing wind and road noise, while artificial sound systems are added for pedestrian safety.

Q15. What role does modular design play in electric vehicles?

Modular platforms allow automakers to build multiple vehicle models on a shared base, making production more flexible and cost-effective.

Q16. How is charging infrastructure considered in electric vehicle design?

EVs are designed with universal or proprietary charging ports that ensure compatibility with charging networks and varying power outputs.

Q17. How does battery technology influence the overall design of an EV?

Battery size, weight, and energy density are primary factors shaping the vehicle’s chassis, weight distribution, and overall architecture.

Q18. What innovations in EV design are being explored for future models?

Future EV designs include solid-state batteries, wireless charging, improved range, autonomous driving integration, and sustainable materials.

Q19. How do electric vehicle designs prioritize energy efficiency?

EV designs focus on lightweight materials, optimized aerodynamics, and efficient power electronics to maximize energy efficiency and range.

Q20. What is the impact of charging speed on electric vehicle design?

Faster charging speeds require advanced thermal management and robust electrical systems, which influence the vehicle’s overall design and battery architecture.

The design of electric vehicles is an intricate process that merges cutting-edge technology with a commitment to sustainability and user-centric innovation. From the layout of the powertrain to the integration of advanced software systems, every aspect of EV design plays a role in shaping the future of transportation. As the industry evolves, continued advancements in battery technology, materials science, and software integration will drive the next generation of electric vehicles, making them more efficient, affordable, and accessible to consumers worldwide.

The journey toward widespread EV adoption is not just about creating electric vehicles but about redefining the very essence of automotive design, making cars smarter, cleaner, and more connected than ever before. The future of electric vehicle design holds exciting possibilities, promising a more sustainable and technologically advanced world of mobility.

Click here to learn more about Electric Vehicle Design

Click here to learn more about Electric Vehicle Depreciation Rate